REXFAB BLOG

Strengthening Ties with PMMI: A Distinguished Visit to Rexfab

On August 22nd, Rexfab was honored to host Andrew Dougherty, VP of Member Services at PMMI. The visit allowed us to showcase our innovative solutions and learn more about PMMI’s vision for the future.

CAROLINA FOODS QUALITY SERVICE AND SCALABILITY THROUGH INNOVATION

Dan Myers, CEO of Carolina Foods, provides some insight on the baking company’s new facility in Pineville, NC and the opportunities for expanded capabilities it will present upon completion.

ELECTROMAGNETS AND ITS IMPACT ON THE BAKERY FOOD INDUSTRY

Compressed air systems are ubiquitous in manufacturing environments, serving as a power source for pneumatic tools, conveyors, and automation systems. Despite their widespread use, these systems are notoriously inefficient, with energy losses that translate into higher operational costs and environmental burden. As industries strive for sustainability and cost-effectiveness, re-evaluating the role of compressed air in manufacturing becomes imperative.

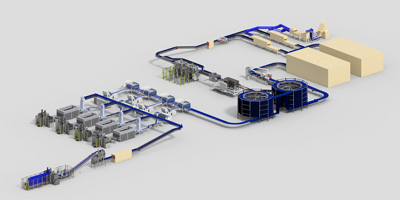

CASE STUDY – SWIFT AND VERSATILE BREAD PRODUCTION LINE – PACKAGING

In the pursuit of growth and competitiveness, enhancing manufacturing capabilities emerges as a pivotal objective for businesses.

In this case we aided our customer in identifying key variables essential for ‘increasing” the manufacturing capacity of their bread line, prioritizing reliability and cost process efficiency.

UNVEILING THE HIDDEN CHAMPIONS: HOW CONVEYORS REVOLUTIONIZE THE INDUSTRIAL BAKING PROCESS

How important are conveyors in the baking world, you ask? Let us put it this way. Without conveyors, you would, be asking a symphony orchestra to perform a masterpiece without a conductor. That is right—it would be complete chaos.

PROMOTING WORKPLACE SAFETY: A PROFITABLE STRATEGY FOR BUSINESS SUCCESS

In the bustling world of industrial bakeries, safety and efficiency drive success. Our latest article, ‘Promoting Workplace Safety: A Profitable Strategy for Business Success,’ reveals how adopting robust safety measures transcends compliance, becoming a catalyst for productivity and profitability. Unveil the symbiotic relationship between quality and safety, understand the real costs of neglecting workplace safety, and explore how technological innovations like Rexfab’s Inline Vacuum Depanner (IVD) are pivotal in safeguarding both employees and the bottom line. Dive into our comprehensive case study and learn why safety isn’t just right—it’s smart business

JUST BAGELS UPGRADING PACKAGING TECHNOLOGY

Cliff Nordquist, president of Just Bagels, shares how a successful supplier partnership allowed the bakery to scale up its packaging processes.

REXFAB AND R&R: A POWERHOUSE PARTNERSHIP IN THE FOOD PROCESSING INDUSTRY

In an ever-evolving world of food processing, efficiency and quality are non-negotiable. It’s not just about getting products from point A to point B anymore—it’s about delivering exceptional quality, unmatched reliability, and innovative solutions that fuel growth and success for businesses.

Today, we’re thrilled to announce a partnership that promises to redefine the standards of the food processing industry: Rexfab’s partnership with R&R.

CASE STUDY: JUST BAGELS

When you’re in the business as long as we have, you come to recognize the genuine expertise when you see it. And Jim Bonatakis has been our go-to for over 25 years for all things related to packaging machinery. We’ve had our fair share of challenges, and every single time, Jim was right there with the solutions we needed.

So, when Jim talked to us about Rexfab and the cutting-edge technology they brought to the table through their own technology, as well as partners integrations, we were all ears. And boy, are we glad we listened!

IVD INLINE VACUUM DEPANNERS SELECTION

Depanning is a vital step in bakery operations. Choosing the right equipment, like Rexfab’s Inline Vacuum Depanner (IVD), can significantly improve this process. The IVD is designed to automate depanning and integrate into your bakery’s complete pan handling operations. It is available in three models, offering a range of widths to suit different bakery sizes and production volumes. The IVD stands out for itsdesign improved sanitation, reduced power consumption, and low-decibel operations, making it a top choice for bakeries looking to enhance their depanning process.

INNOVATIVE TECHNOLOGIES FOR COST REDUCTION IN INDUSTRIALIZED BAKERIES

In an increasingly competitive market, industrialized bakeries are seeking innovative ways to reduce costs and maintain profitability. This article will explore the cutting-edge technologies that are helping these businesses achieve their goals, while also increasing efficiency, minimizing waste, and maintaining product quality. Join us on this journey as we delve into the world of automation, energy efficiency, smart packaging, and data-driven decision-making.

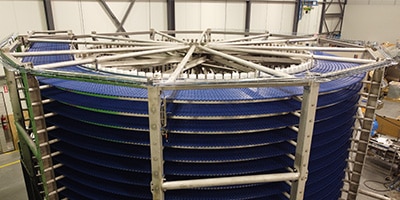

PRESENTING SPIRAL COOLER WITH DIRECT DRIVE TECHNOLOGY

If you are in the industrial baking industry, you know that spiral coolers are an essential component of the post-baking process. These machines ensure that your products cool down quickly and evenly, which is crucial to maintain their quality and freshness. However, traditional spiral coolers have several drawbacks that can impact production efficiency and maintenance costs. That is where Direct Drive Technology comes in.