1.- Introduction

2.- Solution

3.- Results

Customer: Wholesale Bakery in US *

Introduction:

In the pursuit of growth and competitiveness, enhancing manufacturing capabilities emerges as a pivotal objective for businesses.

We aided our customer in identifying key variables essential for ‘increasing” the manufacturing capacity of their bread line, prioritizing reliability and cost process efficiency.

Our initial step involved analyzing:

- Demand requirements

- Product variety

- Size variations

- Tolerances

- Packaging types

- Closures

- Available plant space

Subsequently, we addressed production inefficiencies through the introduction of automation solutions, aimed at enhancing manufacturing capabilities.

Automation not only reduces errors and increases production speed but also facilitates scalability, thereby enhancing overall efficiency. With this in mind, we scrutinized all manufacturing processes, from oven discharge to loading docks.

We opted to prioritize the packaging process for this project, postponing cooling and post-packaging processes to a later stage.

Implementing packaging solutions integrated with modern technology and ensuring equipment reliability is vital to meet the demands of increased production volumes and complexities. Modular packaging allows for flexibility to adapt to changes in overall line capacity.

At Rexfab, we understand the importance of robust training programs to develop a skilled workforce capable of operating advanced machinery and understanding modern manufacturing processes. These capabilities were pivotal to meeting the expanded manufacturing requirements outlined by our customer.

Adhering to regulatory and safety standards and environmental regulations was a non-negotiable requirement from our customer.

The products varied significantly in size, necessitating a solution that offers flexibility without compromising reliability.

Product dimensions ranged as follows:

Product length: + 4 1/8 in with a tolerance of +/- 1/32 in.

Product width: + 2 3/8 in with a tolerance of +/- 1/32 in.

Product height: + 5/8 mm with a tolerance of +/- 1/32 in.

Manufacturing line capacity was +7,200 loaves/hr.

+7 product varieties

Our customer underscored the critical importance of financial investment and risk management in evaluating the project. In response to our customer’s needs, we proposed leveraging the Rexfab “Brainstorming Design” partner process to identify optimal solutions, coupled with our diligent project management approach, fostering close collaboration with our team.

After months of meticulous planning and analysis, the customer decided to proceed with executing the project alongside Rexfab, a decision we deeply appreciate.

Solution

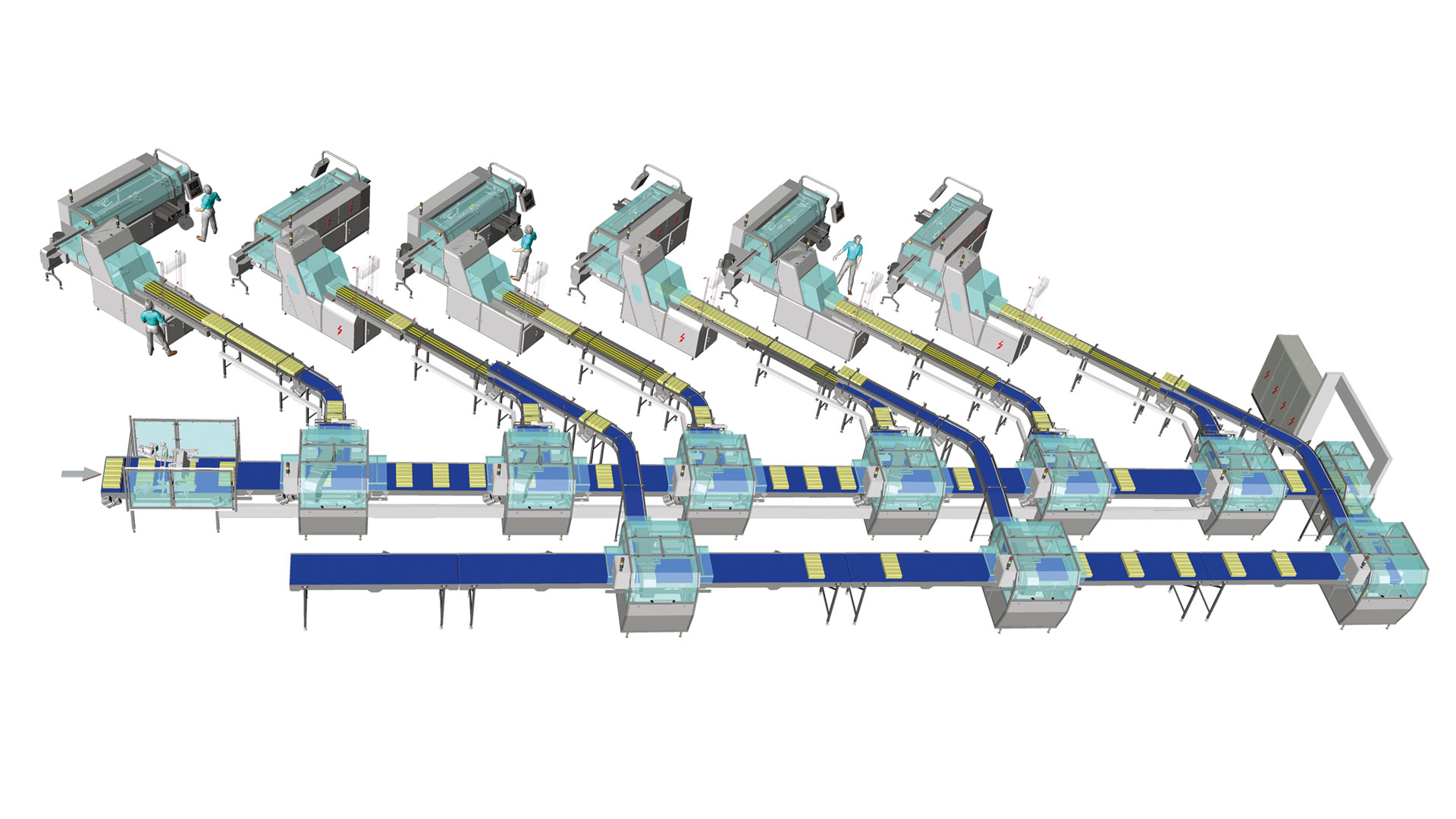

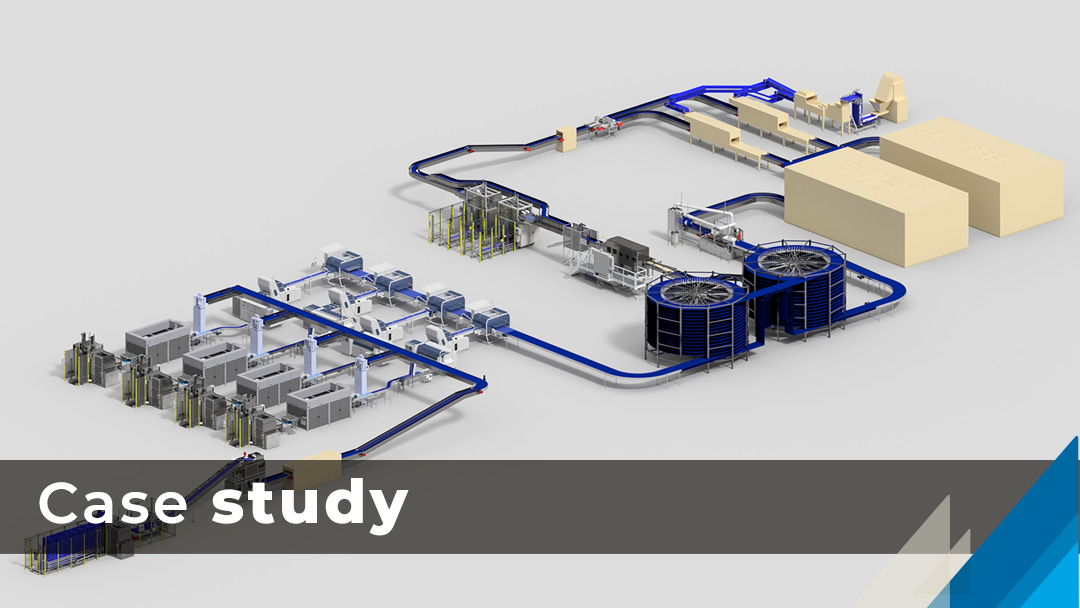

Rexfab has formed strategic partnerships with GHD Hartmann in Germany and SR Pack in Denmark, enabling us to provide an integrated high-speed bread distribution, slicing, and bagging system. This comprehensive solution includes:

- Rexfab Slicer Feed conveyors and horizontal switch, transporting products from the customer overhead cooler to the infeed of the GHD Hartmann distribution system.

- GHD Hartmann automated bread distribution system SLVS and associated controls.

- Four Hartmann bread slicers model SL30XLS, each featuring adjustable blade guides and oiling systems.

- Four Hartmann bread baggers model GBK420, each equipped with discharge flighted conveyors and UL certification.

The packaging system was meticulously designed to align with the overall production speed of the line, which operates at 7200 loaves per hour.

Our solution addressed specific product requirements, incorporating multi-baggers to accommodate diverse packaging needs. While certain products were designated for both over-wrapping and bagging, others were exclusively for bagging. Furthermore, the integration of multi-baggers broadened the range of packaging options available. In this project, the customer took responsibility for sourcing the over-wrappers and multi-baggers, while Rexfab oversaw their mechanical and electrical integration with the proposed GHD Hartmann system.

Rexfab’s Slicer Feed system comprises product conveyors and a 1 in / 2 out horizontal slat-style switch, which automatically balances the flow of bread.

Rexfab stainless steel product conveyors feature support legs, hangers, or supports for elevations exceeding 72 inches. They are equipped with shaft-mounted variable-speed high-efficiency gear motors from SEW-Eurodrive, modular plastic belting, and tight-transfer assemblies to ensure efficient transfers between conveyor sections. Additionally, a low maintenance robust horizontal slat-style switch, equipped with reinforced welded slat rods and operator removable safety guarding.

We included an automatic grouping system for sliced breads fed from a buffer or line distribution system. Products were unevenly fed across rows and then collected, aligned, and arranged longitudinally in rows within the grouping unit.

The GHD Hartmann Sidewise Pusher System 30° model CP 30 serves as a distribution and buffer system for bread loaves. It pushes individual rows of bread loaves transversely to the infeed direction, automatically moving complete rows of bread into the slicing and packaging line or another system upon release.

Hartmann Utilities for Line Distribution system – SLVS contains all the necessary components to control Hartmann conveying and handling systems, facilitating product distribution, buffering, or feeding within the overall system. This includes motor VFD’s, electrical hardware, cable guides, switching devices, and control mechanisms.

The Hartmann Selectra Slicers Model SL 30 XLS are fully automated band-slicing machines designed for toast and multi-grain rye breads. These machines feature heavy-duty band blades tensioned between two hard-chrome plated drums, ensuring smooth operation. Generously sized doors and hoods enable easy access for cleaning, maintenance, and blade replacement.

The Hartmann Bagger Model GBK-420 guarantees optimal packaging and sealing. Two alternately operating product sliders ensure maximum capacity utilization, making this packaging machine highly efficient. Its versatility allows it to meet current market requirements and trends in the packaging sector while adhering to cleanroom standards by separating the product work area from the mechanical drive.

Results

By thoroughly meeting the essential needs, we empowered our clients to effectively enhance their manufacturing capacities, securing competitiveness in ever-changing market landscapes, satisfying consumer expectations, and seamlessly integrating current equipment, which will undergo upgrades in subsequent project phases.

* The real name of the client cannot be disclosed due to a non-disclosure agreement (NDA).

CAROLINA FOODS QUALITY SERVICE AND SCALABILITY THROUGH INNOVATION

Dan Myers, CEO of Carolina Foods, provides some insight on the baking company’s new facility in Pineville, NC and the opportunities for expanded capabilities it will present upon completion.

ELECTROMAGNETS AND ITS IMPACT ON THE BAKERY FOOD INDUSTRY

Compressed air systems are ubiquitous in manufacturing environments, serving as a power source for pneumatic tools, conveyors, and automation systems. Despite their widespread use, these systems are notoriously inefficient, with energy losses that translate into higher operational costs and environmental burden. As industries strive for sustainability and cost-effectiveness, re-evaluating the role of compressed air in manufacturing becomes imperative.

UNVEILING THE HIDDEN CHAMPIONS: HOW CONVEYORS REVOLUTIONIZE THE INDUSTRIAL BAKING PROCESS

How important are conveyors in the baking world, you ask? Let us put it this way. Without conveyors, you would, be asking a symphony orchestra to perform a masterpiece without a conductor. That is right—it would be complete chaos.