When you’re in the business as long as we have, you come to recognize the genuine expertise when you see it. And Jim Bonatakis has been our go-to for over 25 years for all things related to packaging machinery. We’ve had our fair share of challenges, and every single time, Jim was right there with the solutions we needed.

So, when Jim talked to us about Rexfab and the cutting-edge technology they brought to the table through their own technology, as well as partners integrations, we were all ears. And boy, are we glad we listened!

Enter the new Hartmann Bagel System and the SR Pack case packer – game changers for our operations! Before, we had to rely on manual labor, with 2 extra employees working on bagging each shift. Now, we’ve been able to streamline that process, thanks to these fantastic machines. But that’s not all.

The Hartmann single lane slicer it’s a marvel. We’ve slashed our blade change times, making our operations more efficient than ever. And let’s talk about the case packer. Previously, we needed 6 or 7 dedicated employees hand-packing. But now, just 2 people manage the entire operation, ensuring our products are packed efficiently without compromising on quality.

To sum it up, partnering with Rexfab has been one of our best decisions. It’s not just about the advanced machinery; it’s about the trust, reliability, and genuine care they’ve shown towards our growth and efficiency.

CAROLINA FOODS QUALITY SERVICE AND SCALABILITY THROUGH INNOVATION

Dan Myers, CEO of Carolina Foods, provides some insight on the baking company’s new facility in Pineville, NC and the opportunities for expanded capabilities it will present upon completion.

ELECTROMAGNETS AND ITS IMPACT ON THE BAKERY FOOD INDUSTRY

Compressed air systems are ubiquitous in manufacturing environments, serving as a power source for pneumatic tools, conveyors, and automation systems. Despite their widespread use, these systems are notoriously inefficient, with energy losses that translate into higher operational costs and environmental burden. As industries strive for sustainability and cost-effectiveness, re-evaluating the role of compressed air in manufacturing becomes imperative.

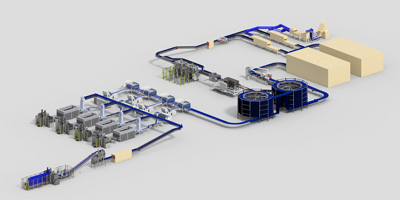

CASE STUDY – SWIFT AND VERSATILE BREAD PRODUCTION LINE – PACKAGING

In the pursuit of growth and competitiveness, enhancing manufacturing capabilities emerges as a pivotal objective for businesses.

In this case we aided our customer in identifying key variables essential for ‘increasing” the manufacturing capacity of their bread line, prioritizing reliability and cost process efficiency.