Table of contents

⏵The Need for Cost Reduction in Industrialized Bakeries

⏵Innovative Technologies in Industrialized Bakeries

⏵Automation and Robotics

⏵The Benefits of Implementing Innovative Technologies

⏵Challenges and Barriers to Adoption

⏵Case Studies

⏵FAQs

Introduction

In an increasingly competitive market, industrialized bakeries are seeking innovative ways to reduce costs and maintain profitability.

This article will explore the cutting-edge technologies that are helping these businesses achieve their goals, while also increasing efficiency, minimizing waste, and maintaining product quality.

Join us on this journey as we delve into the world of automation, energy efficiency, smart packaging, and data-driven decision-making.

The Need for Cost Reduction in Industrialized Bakeries

As the demand continues to grow, industrialized bakeries are under constant pressure to increase production capacity while keeping costs in check. Rising labor and energy costs, along with fluctuating raw material prices, can significantly impact the bottom line.

By embracing innovative technologies, these businesses can stay competitive and better position themselves for long-term success and disruptive markets.

Innovative Technologies in Industrialized Bakeries

Automation and Robotics

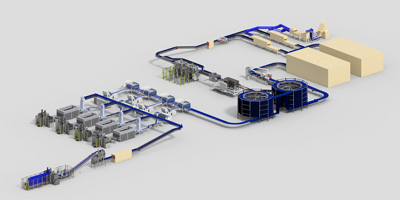

Automation is quickly becoming a game-changer in the baking industry. Robotics and automated systems streamline production processes, reducing labor costs and the risk of human error. For example, robotic arms can handle repetitive tasks such as portioning dough, applying toppings, or even assembling intricate pastries.

Additionally, automated conveyor systems help maintain a consistent flow of products throughout the production line, ensuring efficiency and quality control.

Energy-Efficient Equipment

Energy-efficient ovens, proofers, and other bakery equipment can lead to significant cost savings. Modern ovens equipped with heat recovery systems and insulated panels minimize heat loss, reducing energy consumption.

Additionally, energy-efficient motors and variable frequency drives on mixers and other equipment can lower electricity usage, contributing to a more sustainable operation.

Waste Management Solutions

Reducing waste is crucial for cost reduction and environmental sustainability. Innovative waste management solutions, such as real-time monitoring of ingredient usage, can help identify inefficiencies and areas for improvement.

Furthermore, recycling, or repurposing food waste into animal feed, compost, or even energy production can lead to additional cost savings and a smaller environmental footprint. New materials, automation, and size efficient machinery, also help reducing water in cleaning processes.

Smart Packaging Solutions

Smart packaging solutions not only protect the product but also contribute to cost reduction. Materials that provide better insulation or extend shelf life reduce spoilage and waste.

Additionally, integrating sensors or RFID tags in packaging can enable better inventory management, minimizing stock holding costs and improving supply chain efficiency.

Data-Driven Decision Making

Harnessing the power of data can lead to more informed decisions and better cost management. Advanced analytics tools and software can track production metrics, equipment performance, and energy usage, enabling bakery managers to optimize processes, reduce downtime, and save costs.

The Benefits of Implementing Innovative Technologies

By embracing these technologies, industrialized bakeries can achieve numerous benefits:

- Cost savings: Reduced labor, energy, and material costs lead to improved profitability and competitiveness.

- Increased efficiency: Automation and data-driven decision-making help streamline production processes, allowing bakeries to meet growing demand without sacrificing quality.

- Waste reduction: Implementing waste management solutions and smart packaging minimizes waste, leading to a more sustainable operation.

- Higher product quality: Consistency and precision in production processes ensure that the final products meet the highest quality standards.

Challenges and Barriers to Adoption

Despite the clear benefits, adopting new technologies in the bakery industry can be challenging. Some of the barriers to adoption include:

- High initial investment: The cost of implementing innovative technologies can be prohibitive for smaller businesses or those with limited capital.

- Resistance to change: Some employees may resist automation and new technologies, fearing job loss or the need to learn new skills.

- Technical expertise: The successful implementation of new technologies often requires specialized knowledge, which may not be readily available in-house.

- Integration with existing systems: Integrating new technologies with existing production processes and equipment can be complex and time-consuming.

Case Studies

Case Study 1

A large-scale bakery in the US implemented Smart Packaging Solutions to make it more reliable and sustainable its production processes. The company invested in Rexfab and GHD Hartmann for tasks such as Conveying and Packaging. As a result, they experienced a 1% reduction in packaging costs and a +5% increase in production efficiency.

Case Study 2

A Global bakery focused on gaining scale and people safety. They invested in Post-Packaging Automation, Rexfab Basket Handling Systems, and SR Pack Bread Loaders, leading to over 1 US Million Dollars reduction in labor costs a year. Additionally, by implementing Basket Stacking with Dolly Loader, they were able to reduce injuries by almost 40% and improve the working environment.

Future Trends

As technology continues to evolve, we can expect further advancements in the bakery industry:

- Artificial intelligence (AI): AI-powered systems can help optimize production processes, predict maintenance needs, and improve supply chain management.

- 3D food printing: This technology has the potential to revolutionize the customization and personalization of baked goods, creating new market opportunities.

- Blockchain: Implementing blockchain technology can enhance traceability and transparency in the supply chain, ensuring the highest level of food safety and quality.

Conclusion

Innovative technologies play a crucial role in reducing costs and increasing efficiency in industrialized bakeries. By embracing automation, energy-efficient equipment, waste management solutions, smart packaging, and data-driven decision making, these businesses can maintain competitiveness in a rapidly evolving market.

While challenges and barriers to adoption exist, the long-term benefits of investing in innovation are clear.

FAQs

1. What are some Post-packaging solutions for bakeries?

Post-packaging solutions include SR Pack Basket Loader, as well as Basket Stacker W/WO Dolly Loader and Tortilla Loading in Cases or Baskets and other equipment.

2. How can bakeries gain scale?

Implementing integrated automation and data management solutions such as real-time monitoring of ingredient usage and efficient conveying or Mekitec X-Ray Systems can lead to labor reduction and cost savings.

3. What are the benefits of data-driven decision-making in the bakery industry?

Data-driven decision-making enables bakery managers to optimize processes, reduce downtime, and save costs by tracking production metrics, equipment performance, and energy usage.

4. What are some challenges in adopting innovative technologies in the bakery industry?

Challenges include high initial investment, resistance to change, lack of technical expertise, and integration with existing systems.

CAROLINA FOODS QUALITY SERVICE AND SCALABILITY THROUGH INNOVATION

Dan Myers, CEO of Carolina Foods, provides some insight on the baking company’s new facility in Pineville, NC and the opportunities for expanded capabilities it will present upon completion.

ELECTROMAGNETS AND ITS IMPACT ON THE BAKERY FOOD INDUSTRY

Compressed air systems are ubiquitous in manufacturing environments, serving as a power source for pneumatic tools, conveyors, and automation systems. Despite their widespread use, these systems are notoriously inefficient, with energy losses that translate into higher operational costs and environmental burden. As industries strive for sustainability and cost-effectiveness, re-evaluating the role of compressed air in manufacturing becomes imperative.

CASE STUDY – SWIFT AND VERSATILE BREAD PRODUCTION LINE – PACKAGING

In the pursuit of growth and competitiveness, enhancing manufacturing capabilities emerges as a pivotal objective for businesses.

In this case we aided our customer in identifying key variables essential for ‘increasing” the manufacturing capacity of their bread line, prioritizing reliability and cost process efficiency.