Booth No. 1355 is going to be a destination location at this year’s highly anticipated IBIE 2022 in Las Vegas from September 18-21. We’ll have coffee service every morning, beer service every afternoon and automation, automation, automation!

For the past 14 years, Rexfab has built a reputation in the baking industry for automating post-baking processes. We build our own systems, partner with leading global equipment manufacturers and develop conveyor solutions to integrate and automate production lines.

We’ve got a lot to showcase at IBIE 2022, and here are the top five things we’re excited to be bringing to Las Vegas.

1. Pan Stacker-Unstacker

Our new Pan Stacker-Unstacker delivers what every bakery wants: lower operating costs through automation. The machine’s breakthrough technology comes in the form of a fully electric system using electromagnetic technology and servo motors to ensure smoother, gentler pan stacking and unstacking. The recipe-driven pan stacking solution handles up to 40 pans/minute in a compact footprint. Learn more about our Pan Stacker-Unstacker.

2. Our Team

We’re so excited for our team to be able to see old friends and customers and to meet new people seeking to automate their bakeries. We’ll have 21 people there from Canada and our newly established U.S. operations. Schedule an appointment to meet with one of our team members at IBIE.

3. German Engineering Comes to Las Vegas

Rexfab has partnered with industry leader GHD Hartmann to bring comprehensive slicing and bagging solutions to North American bakeries, and we’ll be exhibiting a GBK 220 bread bagger at the show.

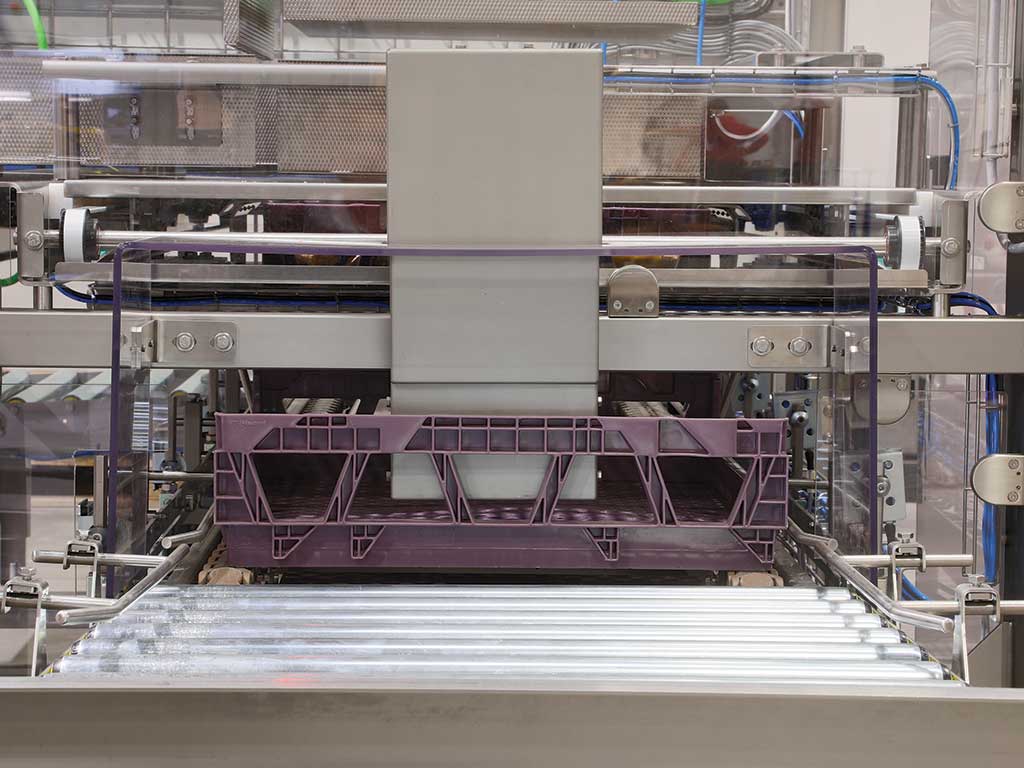

4. SR Pack Loader

We’ve partnered with SR Pack to bring the most advanced basket loader system to North American bakeries. The system is known for its versatility, accommodating multiple packaging patterns in both baskets and boxes. Learn more about the SR Pack Basket Loader.

5. Honest Conversation about ROI

This is important as a challenging economic environment makes equipment decisions even more important. Our team loves to talk to bakers about true ROI, which accounts for the complete lifespan of the equipment. Settling for an ROI on a bread slicer of two years is great if the expectation is that the slicer only lasts two years. What happens if in years three and four, the slicer breaks down continually? That two-year ROI turns out to be a bad deal.

Are you going to IBIE? Let us know and schedule an appointment to have some coffee, drink a beer and talk about how Rexfab can help your bakery.

Strengthening Ties with PMMI: A Distinguished Visit to Rexfab

On August 22nd, Rexfab was honored to host Andrew Dougherty, VP of Member Services at PMMI. The visit allowed us to showcase our innovative solutions and learn more about PMMI’s vision for the future.

CAROLINA FOODS QUALITY SERVICE AND SCALABILITY THROUGH INNOVATION

Dan Myers, CEO of Carolina Foods, provides some insight on the baking company’s new facility in Pineville, NC and the opportunities for expanded capabilities it will present upon completion.

ELECTROMAGNETS AND ITS IMPACT ON THE BAKERY FOOD INDUSTRY

Compressed air systems are ubiquitous in manufacturing environments, serving as a power source for pneumatic tools, conveyors, and automation systems. Despite their widespread use, these systems are notoriously inefficient, with energy losses that translate into higher operational costs and environmental burden. As industries strive for sustainability and cost-effectiveness, re-evaluating the role of compressed air in manufacturing becomes imperative.