For hundreds of years, the popular saying, “cannot see the forest for the trees,” has been levied on people, governments and large corporations that focus so much on minute details that they fail to see the big picture. In the baking industry, we see this all the time when it comes to automation of the big five processes: makeup (preparation & baking), pan return, cooling, packaging and distribution.

These crux points of a production line are massively important and warrant a lot of attention. However, not at the expense of ignoring other aspects of a bakery process that could be automated. Envision this scenario. A technologically-advanced production line that essentially eliminates operators from mixing through packaging. We’re talking state-of-the-art everything — a plant that could run in the dark.

However, once products have been packaged, you see a slew of bakery employees manually loading trays or corrugated cases, then manually stacking them on dollies or pallets , where a different set of operators bring the trays and pallets to the shipping docks.

It’s a common sight, in some iteration or another, to see automated processes operating up to, or next to, manual processes. Often, automating these manual subprocesses (as we call them at Rexfab) provide just as much opportunity as the core production processes to increase efficiencies, reduce labor and maximize profitability.

Take for example the subprocess of pan stacking-unstacking. Rexfab can automate this subprocess from infeed conveyors to outfeed conveyors that deliver pans back to the start of the production line or that automatically stacks them on pan carts or an automated storage system. It’s an area where multiple operators can exist, but when integrated as part of the entire bakery production line, one or fewer operators is needed to oversee the process.

Automation and Integration of Bakeries

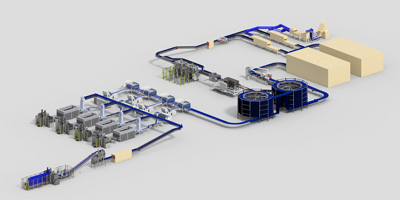

In a bakery, subprocesses don’t operate in a vacuum. In fact, nothing in a bakery operates in a vacuum. Everything is interconnected and integrated, if not by conveyors, then by humans. When Rexfab works with a bakery to increase productivity through automation, we make a full assessment of the bakery’s processes.

We review how a bakery has automated its core baking processes and analyze how to further integrate subprocesses such as pan cleaning, pan stacking, basket stacking and empty basket distribution into the overall process flow.

It’s relatively easy to design a process flow on a computer, make the drawings and produce them. However, there is much more to a production line than process flow. We also factor in touch points beyond core baking processes, production rates over the course of a shift, labor usage and allocations, and even company culture.

By reviewing all aspects of production, not just the core processes, our Rexfab engineers gain insight into the entire forest, not just the trees. At this point, we can design an automated process flow that accounts for core processes and subprocesses that bring true profitability to a bakery.

After you get done reading this blog, head down to your production floor and observe where your operators and employees are working. Most likely it’s a subprocess that can be automated. Most likely, Rexfab can help you.

Contact us to get started on automating bakery subprocesses.

CAROLINA FOODS QUALITY SERVICE AND SCALABILITY THROUGH INNOVATION

Dan Myers, CEO of Carolina Foods, provides some insight on the baking company’s new facility in Pineville, NC and the opportunities for expanded capabilities it will present upon completion.

ELECTROMAGNETS AND ITS IMPACT ON THE BAKERY FOOD INDUSTRY

Compressed air systems are ubiquitous in manufacturing environments, serving as a power source for pneumatic tools, conveyors, and automation systems. Despite their widespread use, these systems are notoriously inefficient, with energy losses that translate into higher operational costs and environmental burden. As industries strive for sustainability and cost-effectiveness, re-evaluating the role of compressed air in manufacturing becomes imperative.

CASE STUDY – SWIFT AND VERSATILE BREAD PRODUCTION LINE – PACKAGING

In the pursuit of growth and competitiveness, enhancing manufacturing capabilities emerges as a pivotal objective for businesses.

In this case we aided our customer in identifying key variables essential for ‘increasing” the manufacturing capacity of their bread line, prioritizing reliability and cost process efficiency.