Rexfab solutions are crafted to handle every baked good with precision, reliability, and care.

Scroll for more information

Rexfab’s specialized bakery equipment

enhances production efficiency, maintains consistent quality, and ensures cost-effectiveness for all bakery categories.

PRODUCT CATEGORIES

BREAD

Gentle handling and precise slicing for consistent, high-quality bread production.

BUNS & ROLLS

Efficient equipment for uniform, high-volume bun and roll manufacturing.

BAGELS

Durable systems designed to preserve texture and quality in bagel production.

SNACK CAKES

Delicate handling ensures premium presentation and efficiency for snack cakes.

DONUTS

Reliable solutions for consistent shape, freshness, and efficiency in donut production.

MUFFINS

Gentle systems protect muffins’ structure while boosting production efficiency.

ENGLISH MUFFINS

Precision equipment maintains texture, taste, and quality every batch.

PASTRIES - DANISH

Specialized systems preserve flaky layers while ensuring efficient pastry production.

TORTILLAS

High-capacity solutions deliver uniform tortillas and flatbreads with reliability.

Automation starts with a conversation

Interested in the right equipment for your products?

Contact us to explore tailored solutions for your bakery line.

Insights, innovations, and expert tips to keep your bakery running at peak performance.

IVD INLINE VACUUM DEPANNERS SELECTION

Depanning is a vital step in bakery operations. Choosing the right equipment, like Rexfab’s Inline Vacuum Depanner (IVD), can significantly improve this process. The IVD is designed to automate depanning and integrate into your bakery’s complete pan handling operations. It is available in three models, offering a range of widths to suit different bakery sizes and production volumes. The IVD stands out for itsdesign improved sanitation, reduced power consumption, and low-decibel operations, making it a top choice for bakeries looking to enhance their depanning process.

INNOVATIVE TECHNOLOGIES FOR COST REDUCTION IN INDUSTRIALIZED BAKERIES

In an increasingly competitive market, industrialized bakeries are seeking innovative ways to reduce costs and maintain profitability. This article will explore the cutting-edge technologies that are helping these businesses achieve their goals, while also increasing efficiency, minimizing waste, and maintaining product quality. Join us on this journey as we delve into the world of automation, energy efficiency, smart packaging, and data-driven decision-making.

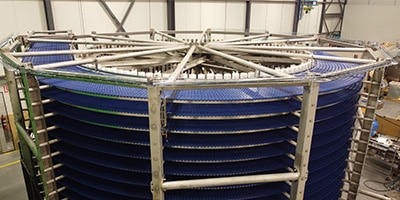

PRESENTING SPIRAL COOLER WITH DIRECT DRIVE TECHNOLOGY

If you are in the industrial baking industry, you know that spiral coolers are an essential component of the post-baking process. These machines ensure that your products cool down quickly and evenly, which is crucial to maintain their quality and freshness. However, traditional spiral coolers have several drawbacks that can impact production efficiency and maintenance costs. That is where Direct Drive Technology comes in.