Rexfab automated solutions for realiable, efficient production.

Scroll for more information

Rexfab has garnered a reputation for

our ability to integrate automation into downstream bakery processes.

When you purchase an automated solution from Rexfab,

Why choose

REXFAB EQUIPMENT?

Performance You Can Count On

Each system is designed for high-volume production and tested to meet rigorous standards for durability and hygiene.

Seamless Integration

We build every machine with connectivity in mind—so your conveyors, loaders, slicers, and packaging systems work together as one coordinated line.

Reduced Total Cost of Ownership

Our solutions are engineered to lower maintenance costs, reduce downtime, and deliver long-term value.

Expert Support

From planning and installation to training and service, Rexfab stands behind your investment with dedicated support and proactive assistance.

Automation starts with a conversation

Your

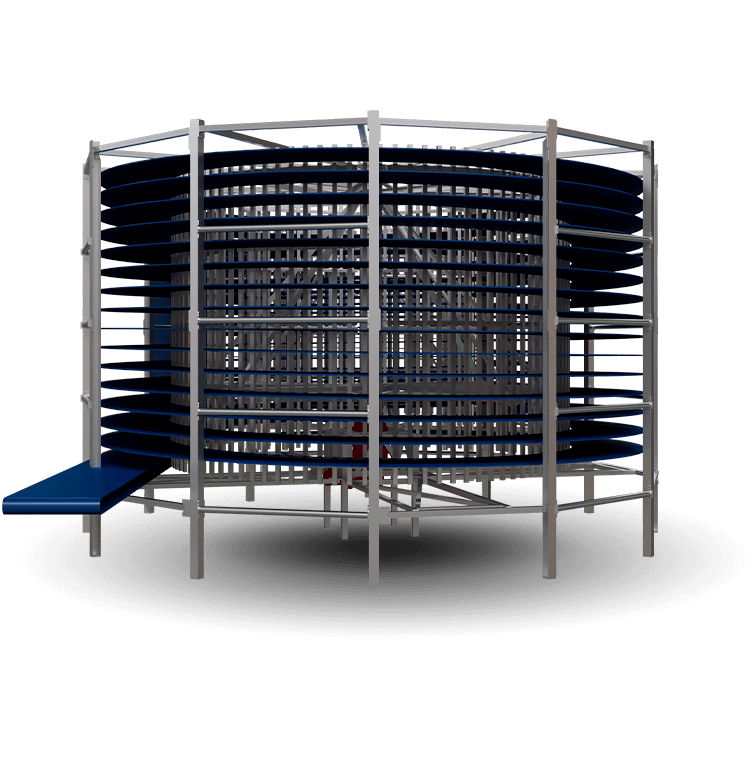

Equipment

Manage pans safely and efficiently with automated systems that stack, unstack, invert, and clean, reducing manual labor and improving workflow.

Systems

Protect product quality with gentle, consistent cooling that prepare your products for slicing and packaging.

Packaging Equipment

Handling Systems

Systems

Let’s build the future of your bakery together

Your production

Ready to build the right solution for your production line?

Contact us today.

Insights, innovations, and expert tips to keep your bakery running at peak performance.

STRENGTHENING TIES WITH PMMI: A DISTINGUISHED VISIT TO REXFAB

On August 22nd, Rexfab was honored to host Andrew Dougherty, VP of Member Services at PMMI. The visit allowed us to showcase our innovative solutions and learn more about PMMI’s vision for the future.

CAROLINA FOODS QUALITY SERVICE AND SCALABILITY THROUGH INNOVATION

Dan Myers, CEO of Carolina Foods, provides some insight on the baking company’s new facility in Pineville, NC and the opportunities for expanded capabilities it will present upon completion.

ELECTROMAGNETS AND ITS IMPACT ON THE BAKERY FOOD INDUSTRY

Compressed air systems are ubiquitous in manufacturing environments, serving as a power source for pneumatic tools, conveyors, and automation systems. Despite their widespread use, these systems are notoriously inefficient, with energy losses that translate into higher operational costs and environmental burden. As industries strive for sustainability and cost-effectiveness, re-evaluating the role of compressed air in manufacturing becomes imperative.