Seamless production

every baked good with precision, reliability, and care.

Scroll for more information

Your bakery’s success depends on much more than individual machines —

That’s why we offer more than equipment. We provide automated, reliable, integrated solutions that transform your production line into a single, efficient system designed around your specific products, throughput, and facility layout.

REXFAB’S APPROACH

Before recommending any equipment, our team takes the time to understand your current processes, challenges, and goals. We analyze how your operations work today—and how they could work better tomorrow. The result is a cohesive line strategy built to:

- Eliminate bottlenecks and inefficiencies

- Reduce manual handling and labor costs

- Improve product quality and consistency

- Scale with your growing production needs

MAKE-UP

Shaping and portioning your dough accurately is the foundation of consistent quality.Our solutions support efficient transfers and gentle handling to protect every product.

PROOFING

Proper fermentation is critical to texture and volume.We help you manage proofing with integrated conveyors and automated staging systems that keep your line moving.

BAKING

Transform dough into finished products with controlled, efficient baking workflows.Our systems ensure seamless transfers in and out of ovens to maintain throughput.

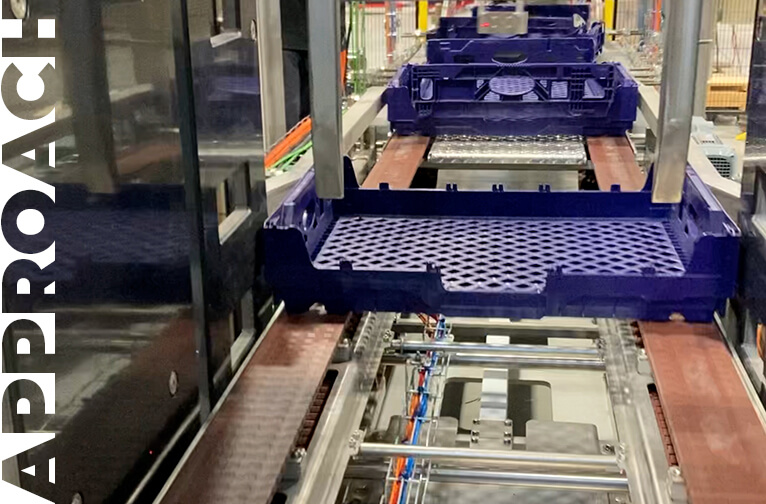

PAN / LID RETURN

Reliable pan and lid return systems keep production flowing without delays or excess handling.

COOLING

Cooling stabilizes product structure and prepares items for packaging.We design cooling systems matched precisely to your volume and space.

PACKAGING

Protect your products with automated slicing, bagging, and closing systems that improve speed and consistency.

POST-PACKAGING

Streamline the final steps of your process with basket loading, dolly stacking, and automated distribution.

Automation starts with a conversation

With decades of experience serving bakeries across North America, Rexfab delivers process solutions you can count on every day.

From concept to commissioning, we stand behind our promise to help you achieve:

- Faster production cycles

- Lower operational costs – best TCO

- Consistent, high-quality output

Interested in the right equipment for your products?

Contact us to explore tailored solutions for your bakery line.

Insights, innovations, and expert tips to keep your bakery running at peak performance.

CASE STUDY – SWIFT AND VERSATILE BREAD PRODUCTION LINE – PACKAGING

In the pursuit of growth and competitiveness, enhancing manufacturing capabilities emerges as a pivotal objective for businesses.

In this case we aided our customer in identifying key variables essential for ‘increasing” the manufacturing capacity of their bread line, prioritizing reliability and cost process efficiency.

UNVEILING THE HIDDEN CHAMPIONS: HOW CONVEYORS REVOLUTIONIZE THE INDUSTRIAL BAKING PROCESS

How important are conveyors in the baking world, you ask? Let us put it this way. Without conveyors, you would, be asking a symphony orchestra to perform a masterpiece without a conductor. That is right—it would be complete chaos.

PROMOTING WORKPLACE SAFETY: A PROFITABLE STRATEGY FOR BUSINESS SUCCESS

In the bustling world of industrial bakeries, safety and efficiency drive success. Our latest article, ‘Promoting Workplace Safety: A Profitable Strategy for Business Success,’ reveals how adopting robust safety measures transcends compliance, becoming a catalyst for productivity and profitability. Unveil the symbiotic relationship between quality and safety, understand the real costs of neglecting workplace safety, and explore how technological innovations like Rexfab’s Inline Vacuum Depanner (IVD) are pivotal in safeguarding both employees and the bottom line. Dive into our comprehensive case study and learn why safety isn’t just right—it’s smart business