In the fast-paced world of industrial baking and food processing, safety isn’t just a compliance requirement – it’s a cornerstone of long-term operational success. At Rexfab, we believe that designing and constructing equipment and conveyor systems with safety at the forefront not only protects people but also significantly boosts productivity while reducing overall operational costs.

A Strategic Commitment to Safety

Rexfab’s approach integrates safety at the earliest stages of equipment design through Prevention through Design (PtD). By proactively addressing potential hazards during the engineering phase, Rexfab equipment significantly reduces workplace risks, minimizing reliance on reactive safety interventions. According to industry data, PtD not only eliminates hazards early but also increases the cost-effectiveness of safety enhancements across the board.

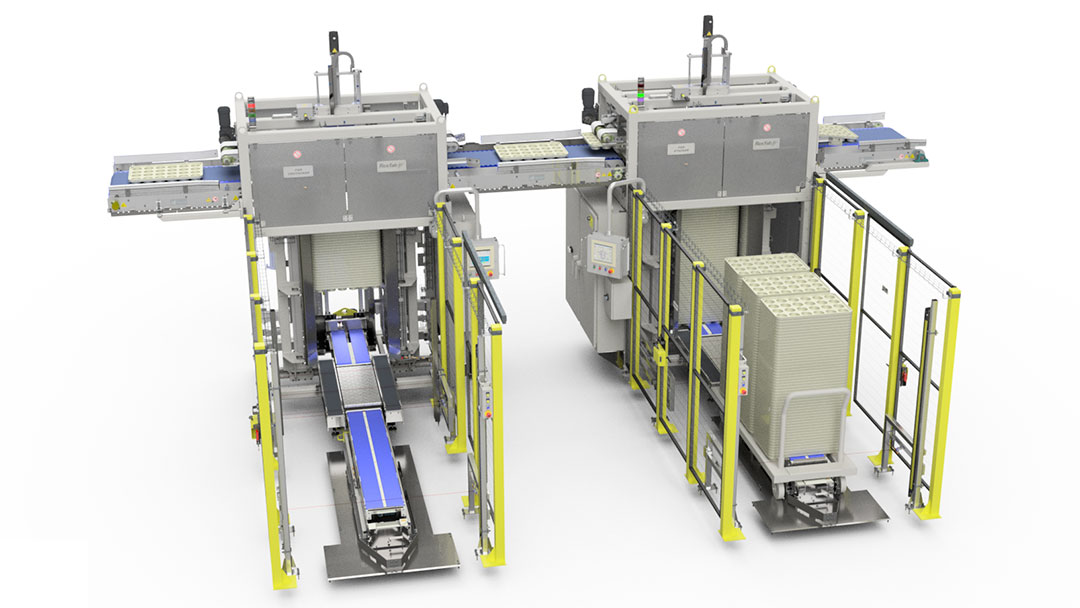

PSPU: Efficiency and Safety Combined

Rexfab’s Pan Stacker Pan Unstacker (PSPU) is an excellent example of how thoughtful design and safety contribute directly to operational efficiency. The PSPU automates the stacking and unstacking of bakery pans, significantly reducing manual handling and potential ergonomic injuries. Its integrated safety sensors and controlled operation ensure minimal risk during use, translating directly into fewer workplace incidents and greater uptime. The PSPU not only protects operators but streamlines the workflow, enhancing overall productivity and profitability.

Inline Vacuum Depanner (IVD): Safety through Automation

The Inline Vacuum Depanner (IVD) stands out in Rexfab’s portfolio. This sophisticated system employs vacuum technology to gently and effectively remove baked products from pans without damage or manual intervention. The IVD features Lexan safety panels and stainless steel enclosures, interlocked safety doors, and automated controls to eliminate risks associated with manual depanning processes. By automating this delicate step, the IVD reduces worker exposure to hazards, cuts down on product waste, and significantly improves throughput and consistency.

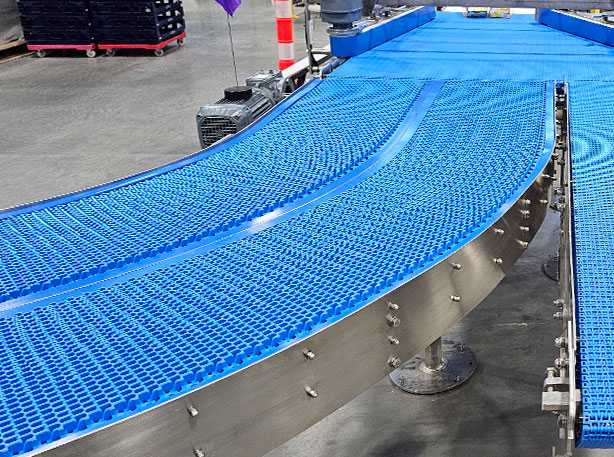

Conveyor Systems: Ergonomically Safe and Efficient

Rexfab’s conveyor systems are engineered for optimal safety and ergonomic operation. These conveyors enhance employee safety and comfort by focusing on appropriate working heights, reducing repetitive movements, and employing intuitive control systems. This not only reduces the risk of injury but also boosts productivity, keeping operations running smoothly.

The Value of Safe Design

Recent studies* show that manufacturers who invest in safety as part of their strategic maturity see:

- 5–7% higher Overall Equipment Effectiveness (OEE)

- 2–4% less unscheduled downtime

- Less than half the workplace injury rate compared to average performers

According to LNS Research, 75% of industrial companies report measurable operational improvements thanks to safety technologies like automation, sensors, and interlocks—features that are core to Rexfab’s solutions.

Key Benefits:

- Reduced Downtime: Equipment designed for safety reduces accidents and maintenance, ensuring consistent production.

- Cost Efficiency: Fewer accidents result in lower insurance costs, reduced healthcare expenses, and fewer regulatory disruptions.

Enhanced Employee Satisfaction: Ergonomic, safe working conditions promote morale, reducing turnover and training costs.

Continual Innovation for Tomorrow

Safety standards and technologies evolve, and so do we. Rexfab remains committed to continuous innovation, consistently updating our equipment designs to exceed emerging safety regulations and industry best practices.

Conclusion

Safety is integral to Rexfab’s engineering philosophy. Whether through advanced automation like the PSPU and IVD systems or ergonomically optimized conveyors, Rexfab’s commitment to safe design drives tangible benefits across the board.

By aligning with industry trends and best-in-class practices, Rexfab delivers solutions that not only meet today’s safety demands but set the standard for tomorrow. Investing in safety is not just essential—it strategically enhances efficiency, profitability, and resilience for long-term success.

WE INVITE YOU TO KNOW MORE ABOUT REXBAF’S SOLUTIONS AND ALL THE ADVANTAGES THE USAGE OF OUR EQUIPMENT PROVIDES.

CONTACT US NOW!

REXFAB – ROBOTIQ WEBINAR – SMART PALLETIZING FOR BAKERIES

Are you a bakery manufacturer navigating labor shortages and ergonomic challenges? Discover how leading bakeries around the world have automated their palletizing processes with minimal disruption and fast ROI.

REXFAB & INTRALOX: A GAME-CHANGER FOR THE BAKING INDUSTRY

Rexfab, an expert in automation solutions for the baking industry, and Intralox, a global leader in innovative conveyor belt solutions, joined forces and have been working together to revolutionize production efficiency and product quality in the baking industry.

STRENGTHENING TIES WITH PMMI: A DISTINGUISHED VISIT TO REXFAB

On August 22nd, Rexfab was honored to host Andrew Dougherty, VP of Member Services at PMMI. The visit allowed us to showcase our innovative solutions and learn more about PMMI’s vision for the future.