Conveyor solutions

for your entire production line.

Scroll for more information

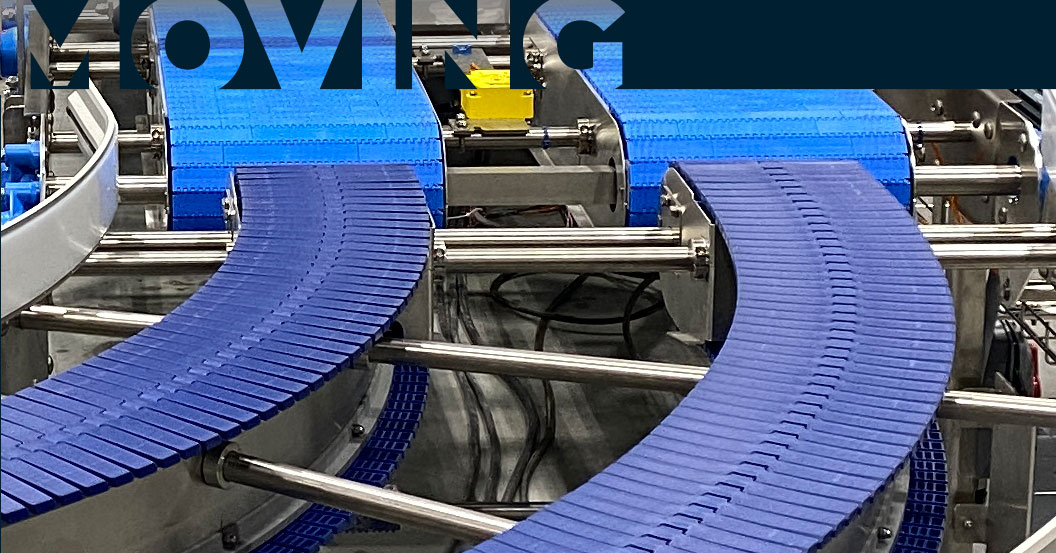

The backbone of automation —

designed to keep your bakery moving. Whether you are transporting pans, baskets, or baked goods.

Rexfab can help automate high-volume production lines in the baking and food industries. Our conveyor solutions are the foundation of your entire operation – designed to meet all production and sanitary requirements.

They feature stainless-steel construction for resilience and ease of cleaning, and modular plastic belting with a variable AC gear motor for optimal performance.

Rexfab conveyors are built to integrate seamlessly, adapt to your space, and support your productivity goals.

KEY

CONVEYOR

APPLICATIONS

Pan Conveyors

Pan conveyors handle the safe, efficient transport of baking pans across your production line—from make-up through baking, cooling, and return.

Applications

- Moving empty pans to make-up areas.

- Transporting loaded pans to proofing or baking.

- Returning pans post-depanning.

Benefits

- Reduced manual handling and labor costs.

- Consistent pan orientation.

- Faster cycle times.

- Easy integration with pan stackers, inverters, and depanners.

Basket Conveyors

Basket conveyors handle empty and filled baskets with precision — automating the flow from packaging areas to storage and shipping, without hassle.

Applications

- Transporting baskets to loaders and stackers.

- Moving filled baskets to dolly loading stations.

- Returning empty baskets for reuse.

Benefits

- Improved workplace safety.

- Reduced manual lifting.

- Streamlined post-packaging handling.

- Faster basket turnaround.

Product Conveyors

Applications

- Moving freshly baked items to cooling systems.

- Transferring cooled products to slicing and packaging.

- In-process staging and accumulation.

Benefits

- Protects product integrity.

- Reduces waste and damage.

- Simplifies line balancing.

- Easy cleaning and sanitation.

Automation starts with a conversation

WHY CHOOSE REXFAB CONVEYORS?

- Purpose-built solutions for bakery production.

- Seamless integration with Rexfab and third-party equipment.

- Modular design for quick installation and maintenance.

- Reliable performance shift after shift.

- Hygienic construction for food safety compliance.

Ready to make conveyors the backbone of your automation?

Contact us for a custom consultation.

Insights, innovations, and expert tips to keep your bakery running at peak performance.

REXFAB – ROBOTIQ WEBINAR – SMART PALLETIZING FOR BAKERIES

Are you a bakery manufacturer navigating labor shortages and ergonomic challenges? Discover how leading bakeries around the world have automated their palletizing processes with minimal disruption and fast ROI.

SAFETY BY DESIGN: HOW REXFAB’S ENGINEERING PHILOSOPHY DRIVES OPERATIONAL EXCELLENCE

In the fast-paced world of industrial baking and food processing, safety isn’t just a compliance requirement – it’s a cornerstone of long-term operational success. At Rexfab, we believe that designing and constructing equipment and conveyor systems with safety at the forefront not only protects people but also significantly boosts productivity while reducing overall operational costs.

REXFAB & INTRALOX: A GAME-CHANGER FOR THE BAKING INDUSTRY

Rexfab, an expert in automation solutions for the baking industry, and Intralox, a global leader in innovative conveyor belt solutions, joined forces and have been working together to revolutionize production efficiency and product quality in the baking industry.